Harmful pollutants called VOCs, or volatile organic compounds, are generated and dispersed into the atmosphere during the manufacturing process of certain products. VOCs have a negative impact on the health of our ecosystem and thus throughout the years, environmental agencies have enforced emission rules for manufacturers.

Oxidizers are one type of pollution control system that manufacturers install in order to adhere to environmental regulations. Catalytic Oxidizers and Thermal Oxidizers have been used to destroy VOCs for over 25 years. Please read our previous blog posts to get an idea on how Catalytic Oxidizers vs. Thermal Oxidizers work to destroy emissions.

| CATALYTIC OXIDIZER | THERMAL OXIDIZER |

| -Used when flow of exhaust is relatively low and the VOC concentration is high. | -Cater to industries with larger volumes. |

| -Used with lower temperature air streams. | -Used with higher temperatures and for higher activity periods. |

| -Metal catalyst monoliths are used to destroy VOCs. | -Used in more industries, since catalyst beds are sensitive to certain VOCs. |

| – Larger initial investment due to the customized catalytic bed. | -Smaller initial investment. |

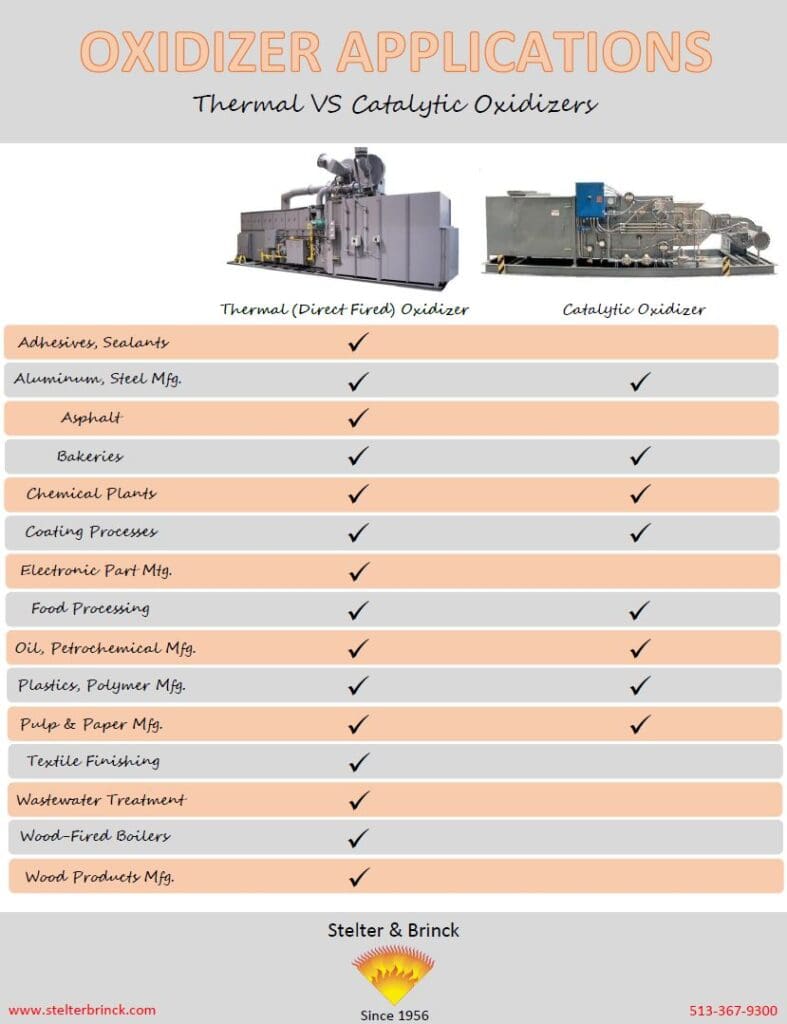

Oxidizers are used when manufacturing adhesives, sealants, aluminum & steel, asphalt, bakery goods, plastics & polymers, pulp & paper, electronic parts, and many other products. See the chart below to differentiate whether your application typically requires a Thermal or Catalytic Oxidizer.

For pictures or more information on these two types of Environmental Systems, please visit our Thermal Oxidizer webpage or our Catalytic Oxidizer webpage. Like always, feel free to contact us with questions