The fourth and final type of dryer that we will discuss that utilizes air heaters is a fluid bed dryer (or fluidized bed dryer). According to Wikipedia: “A fluidized bed is formed when a quantity of a solid particulate substance is placed under appropriate conditions to cause the solid/fluid mixture to behave as a fluid.”

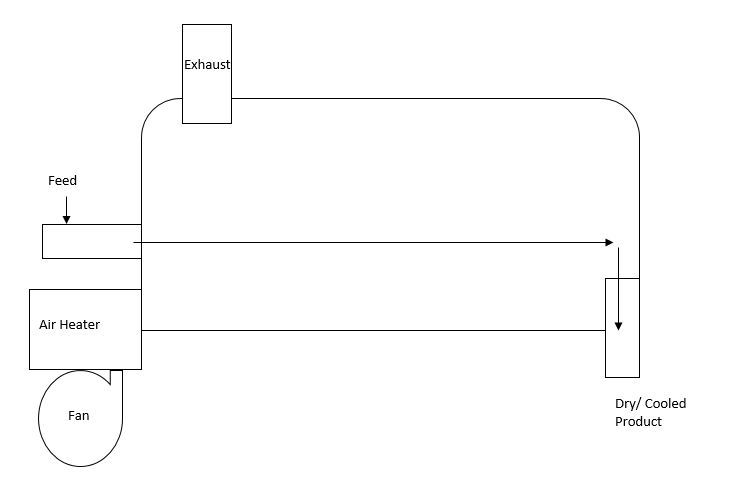

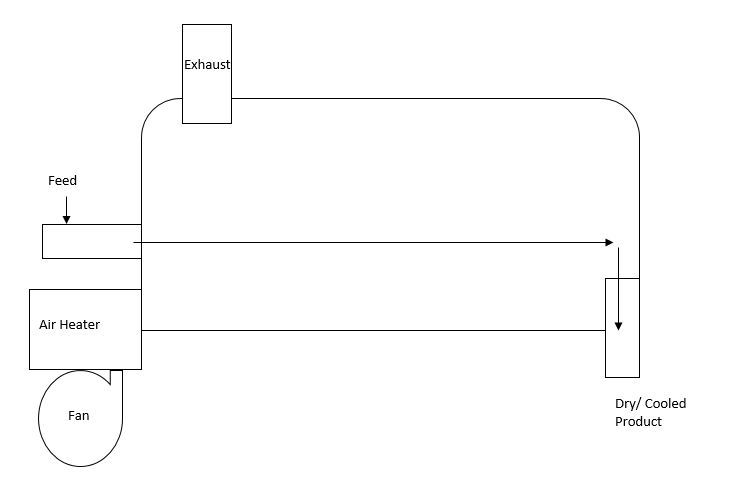

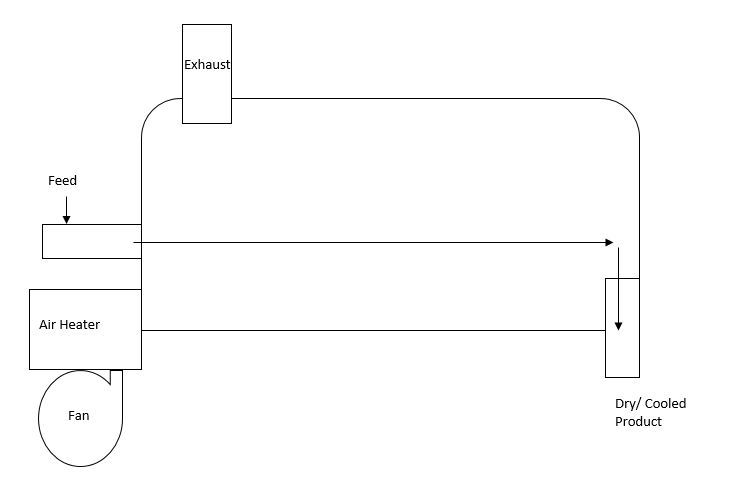

Fluid Bed Diagram

Hot air, generated by either a direct fired air heater or indirect air heater, is passed through the bed of particles. At the right temperature and at a velocity high enough, the particles will be suspended in the dryer vessel and they will flow as if they are fluid. Dust generated from the process is sent through the exhaust, while the dried/ cooled end product is discharged after being sent through the fluid bed.

If you have questions about Stelter & Brinck’s direct or indirect fired air heaters for use with industrial dryers, or for any other application, feel free to contact us!