Some products made with tobacco also require tobacco extracts, such as cigarettes. When manufacturing cigarettes, the paper must be flavored using tobacco extracts. These extracts are generated by:

- Processing the tobacco with water and alcohol to make the tobacco liquescent.

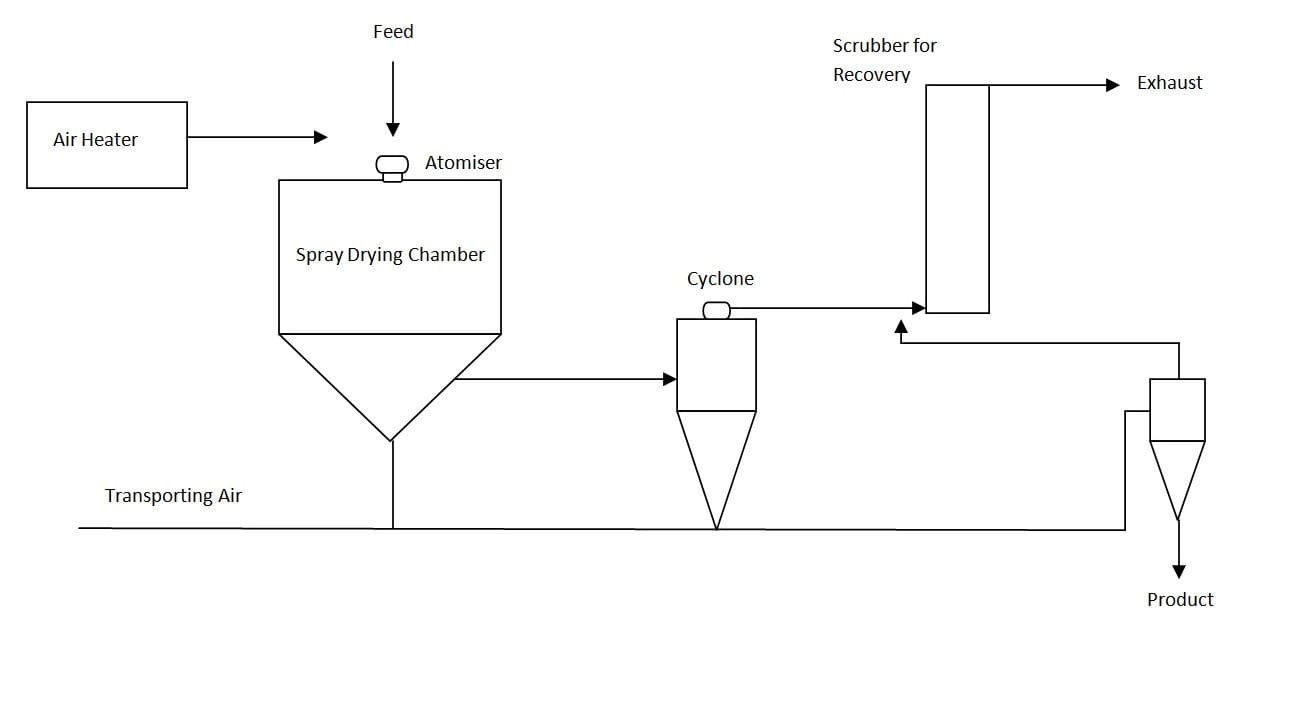

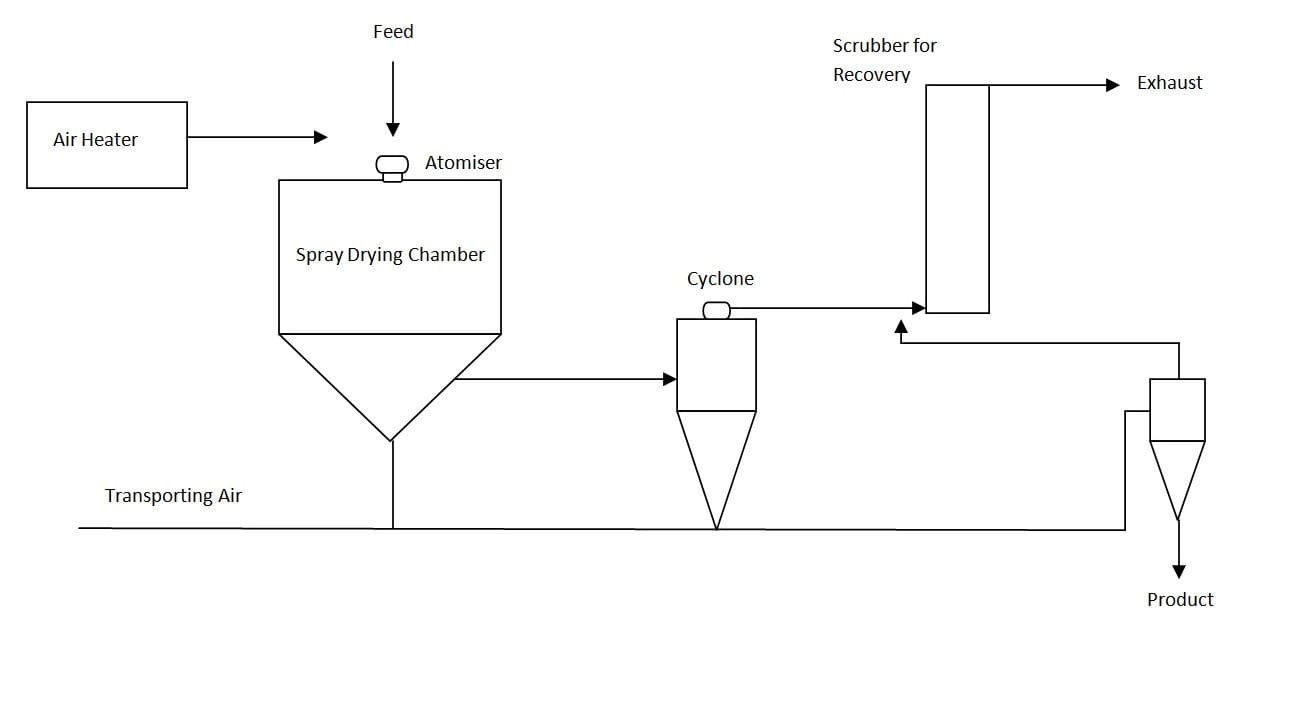

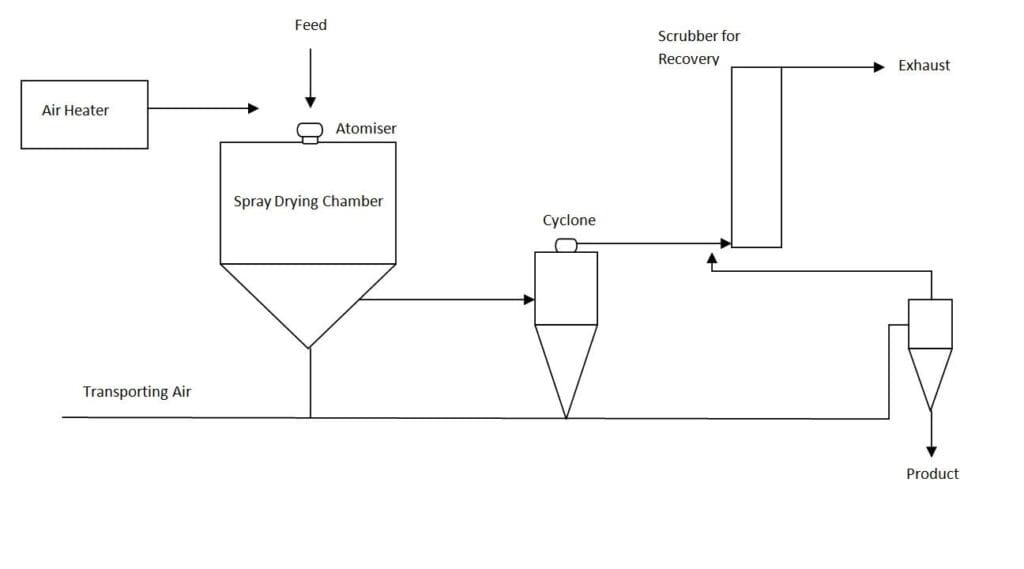

- Using a spray dryer to provide a more concentrated tobacco extract.

In order to create the “smooth” smoke taste that tobacco is known for, the spray dryer uses an indirect fired air heater as the heat source. The tobacco flavor remains “pure” because indirect air heaters do not contaminate the air stream with the by-products of combustion.

- The spray dried tobacco is applied to cigarette paper.

- The paper is sent to production where it is wrapped around the tobacco mix, found inside cigarettes.

For more information on indirect fired process air heaters in tobacco processing, please visit Stelter & Brinck at https://stelterbrinck.com/indirect-fired-air-heaters/