Centuries ago, an Ethiopian goat farmer observed his goats acting full of energy after eating berries from a coffee shrub. Curious, the goat farmer ate a few of these berries himself; finding similar side effects.

A coffee bean is found in the center of a coffee berry. Long before coffee became a popular beverage, it was used for protein bars, fermenting berries to make wine, and assorted fruit drinks.

The British invented roasting coffee beans in the 13th century. Overtime cultures developed many ways of roasting and grinding the coffee bean. In order to decrease volume and increase shelf-life, manufacturers began producing instant coffee. Instant coffee is a soluble powder; it will dissolve in liquid to make a flavorful beverage. Instant coffee is typically manufactured using a spray dryer.

The stages of manufacturing instant coffee with a spray dryer are:

- Coffee beans are finely ground up.

- Hot, soft water is passed through the ground beans multiple times to rid the mixture of unwanted gases.

- Cold water is run through the mixture to extract the bold, rich flavor.

- The concentration is increased by placing this mix into a centrifuge, evaporating excess water before cooling the extract.

- To maximize bold flavor, oxygen is eliminated from the mixture.

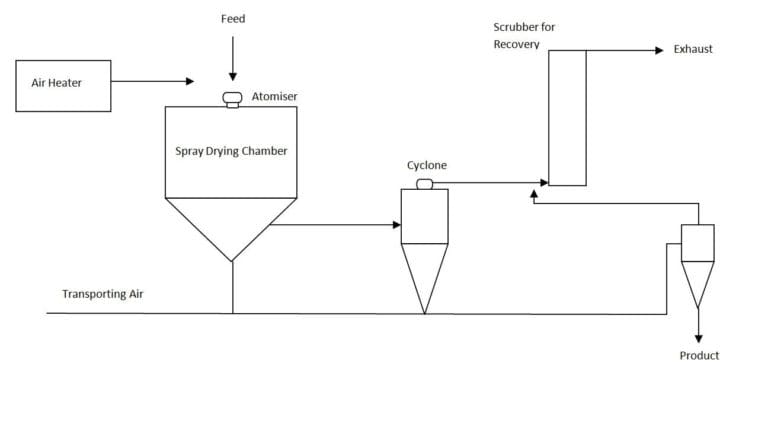

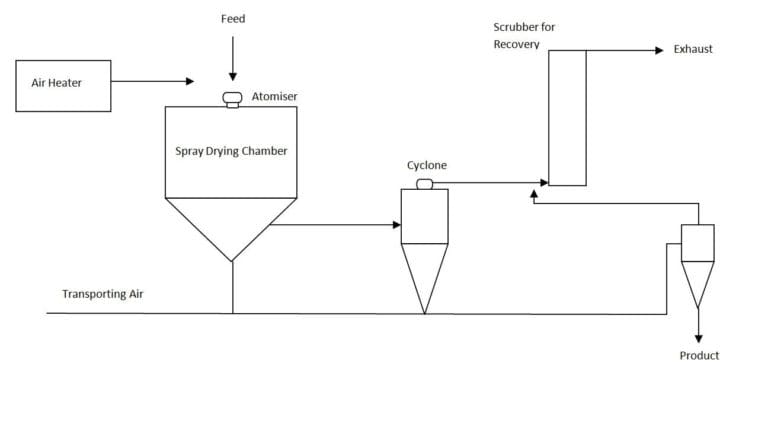

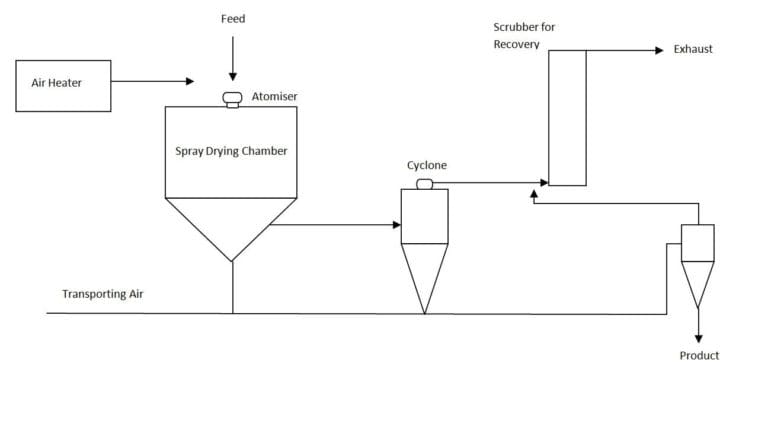

- The mixture is processed through a spray drying system. See the diagram below.

- Hot air passes through the mixture, allowing it to dry. To preserve flavor, an indirect fired air heater is used as the source of hot air; an indirect air heater does not subject the mixture to the by-products of combustion.

- Once the mixture is dry, it is filtered by the cyclone, which breaks it up into very small, powder like particles.

- The coffee grounds are then packaged in a low-oxygen, low-humidity canister to optimize product flavor and consistency.