We have discussed flash and rotary dryers; the third type of industrial dryer that uses a process air heater for hot gas generation is a spray dryer. Spray dryers are known for distributing a consistent particle size and are the most prominent drying system in the food and dairy powder industries. Powdered colors, inorganic chemicals, insoluble organic dyes, and instant mixes are just a few of the items that require spray drying.

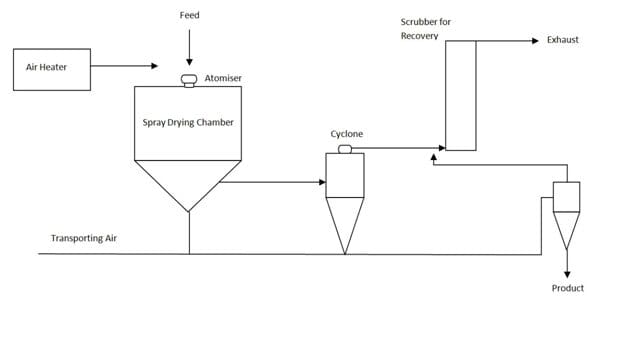

Diagram of a Spray Drying System

Spray dryers use an atomizer to feed liquid into a drying chamber. When the small drops of liquid enter the chamber, they are subjected to hot air, which turns the feed into powder by means of water evaporation. After the drying chamber, the material is separated using cyclones and the dry material is sent to a collection vessel. To meet emission standards, sometimes a scrubber is used with spray dryers.

As you can see from the diagram above, the hot air utilized in the spray drying process is generated by an air heater. Air heaters are classified as either indirectly fired (indirect air heater) or direct fired (direct fired air heater). The type of air heater used depends upon the thermal sensitivity of the feed and thus, an indirect fired air heater is typically used for food, pharmaceuticals, dairy and other chemically sensitive products. Rely on Stelter & Brinck to custom design and manufacture a direct or indirect fired process air heater for your spray drying system!