Integrated Packaged Process Systems

Modular & Skidded Packaged Systems

Stelter & Brinck, Ltd. packaged integrated systems are a result of our customer's exposure to the ever-increasing competitiveness of the global market. We listen when our customers share the feedback they receive in the market place. Our customers are experiencing price and delivery pressure at most every turn. This especially so with the demand for custom equipment designed for specific process needs. It is very expensive for a typical company to utilize resources outside of its core business because the application of their resources becomes less efficient thereby increasing overhead costs, extending deliveries, and limiting the company's core business activity.

Integrated packaged systems can save you weeks and months of installation and commissioning time.

Modular Packaged System

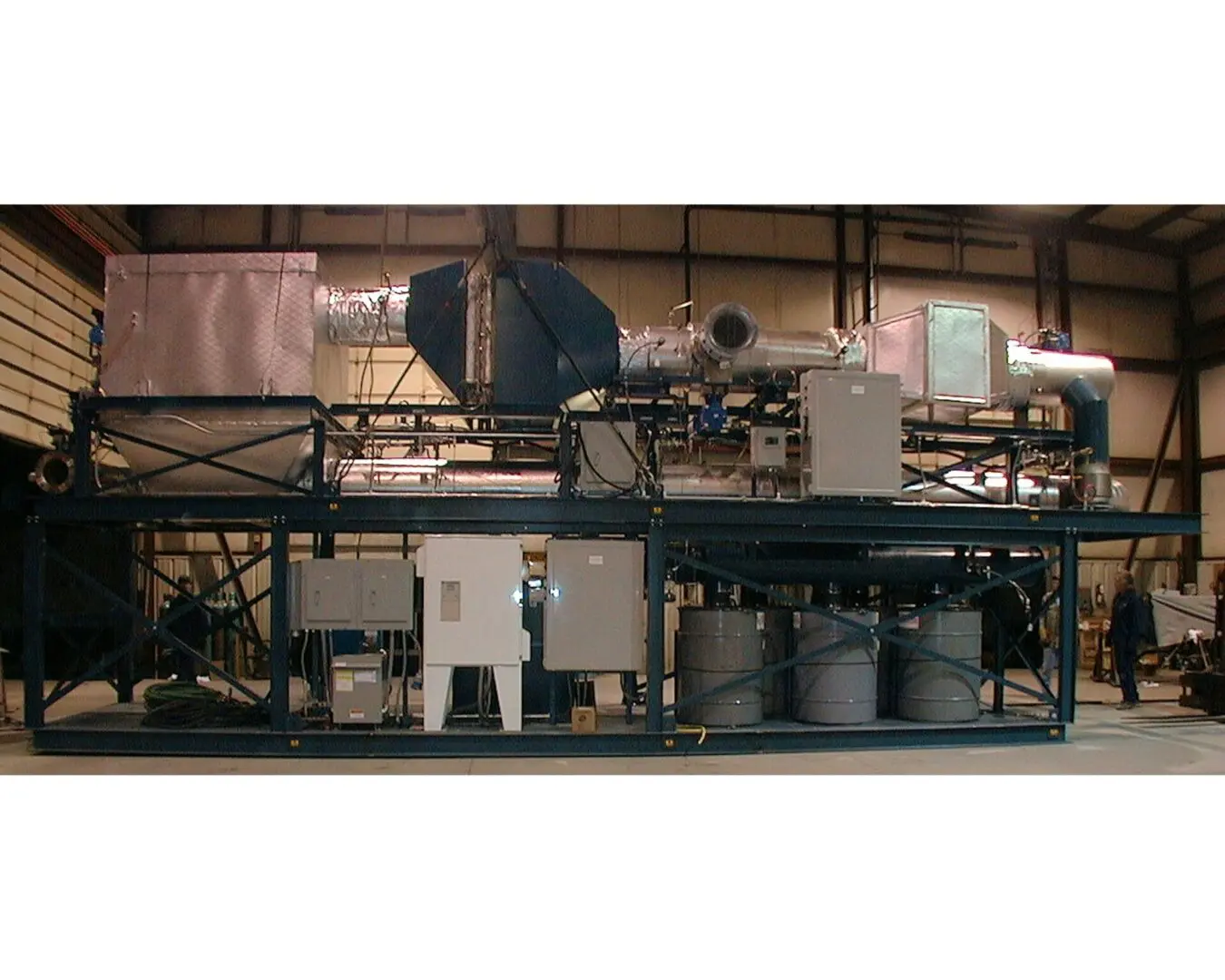

Complete Integrated Packaged System for Chemical Weapon Destruction

Packaged Process System

Among the features of your Integrated System are:

- Built to modern standards of safety, performance, repeatability, and reliability; UL 508A priced per request

- Built to meet your requirement (FM, CE, GAP, NFPA or CSA construction standard)

- Fully packaged and ready to install

- Heavy-duty construction

- Test-fired in our facility before shipment, making start-up trouble free

- On-site start-up and on-going combustion system maintenance available

MODULAR

The above image is just one modular integrated packaged system example, in which S&B provided the following:

- S&B thermal oxidizer

- Test platform

- Insulated stack

- Efficient use of footprint space

- Pre-assembled in our shop

- Skid break for shipping

- Heated and air conditioned control room

SKIDDED

The above images are just one example, in which we integrated the following into a single skid:

- Stelter & Brinck heat recovery heat exchanger

- Combustion blower

- Motor control center for entire plant

- Main process recirculating blower

- Gun style air heaters

- Instrument rack

- Fresh air make up