Blog

Home / Blog

Overview of Catalytic & Thermal Oxidizers

Harmful pollutants are generated during manufacturing, called VOCs or volatile organic compounds. To destroy VOCs...

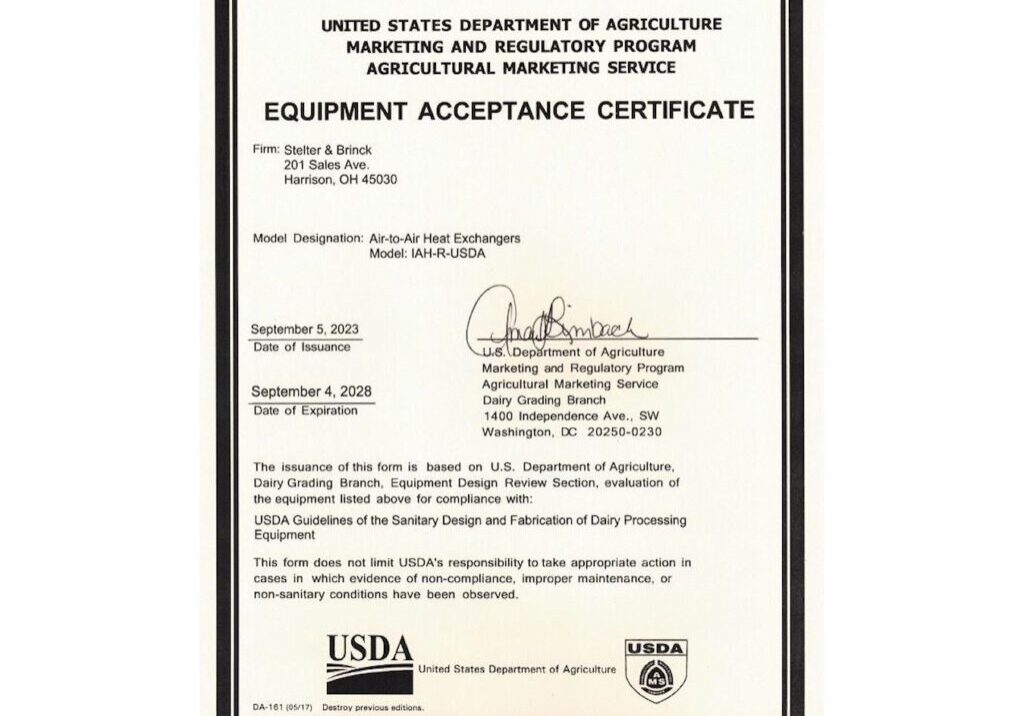

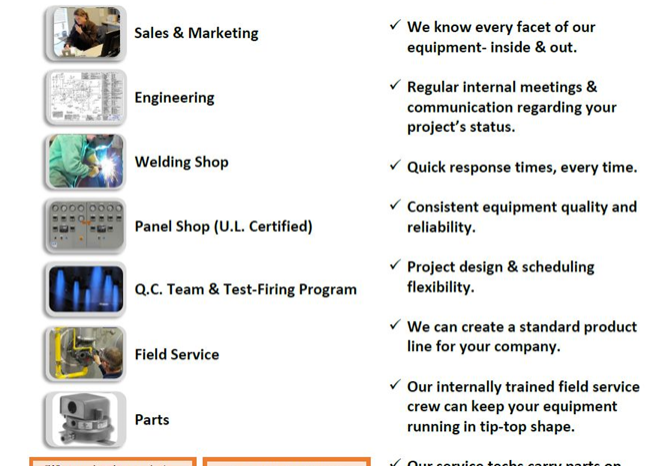

The Stelter & Brinck “In-House” Advantage

We take pride in handling every aspect of your project- from concept to departure- every...

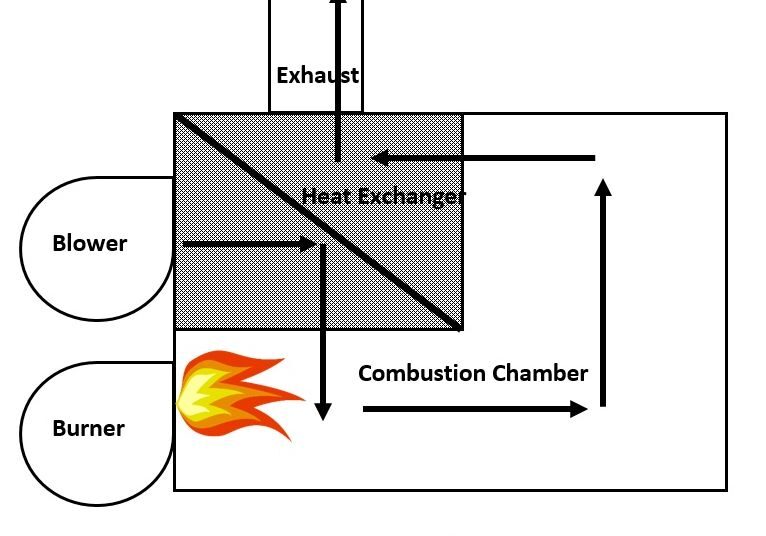

Indirect Air Heater for Small Footprint

A product of more than 100 years of process heat equipment experience, our vertical indirect...

Industrial Air Heater Vs. HVAC Air Handler

What is an industrial air heater? How is it different from HVAC equipment? What is...

2023 Food Drive Results

At the beginning of October, Stelter & Brinck hosted our 9th Annual Food drive, benefiting...